Air Flow and Thermodynamics

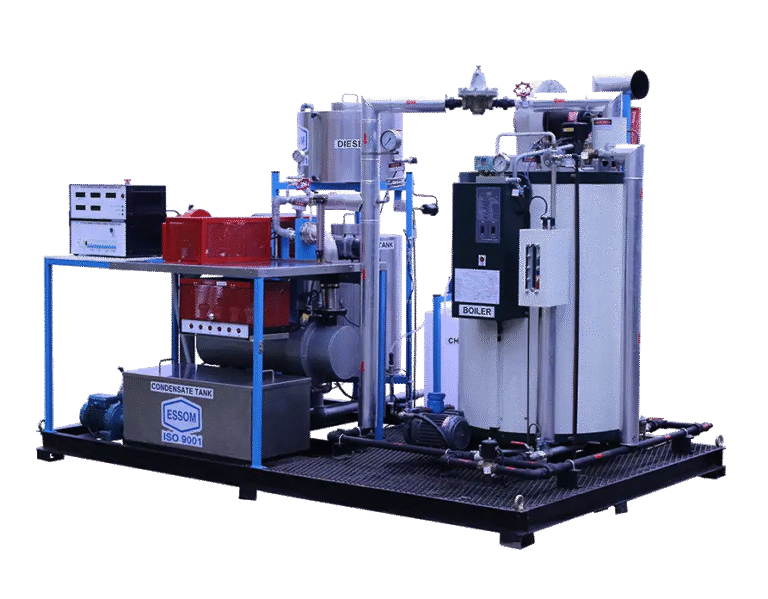

Compact Steam

Turbine Power Plant 1.5 kW

The unit is designed to simulate modern steam power plant. Main components consist of a feed water system, a small industrial boiler, a steam turbine, a generator and lamp load, a condenser with a condensate tank and a pump, and…

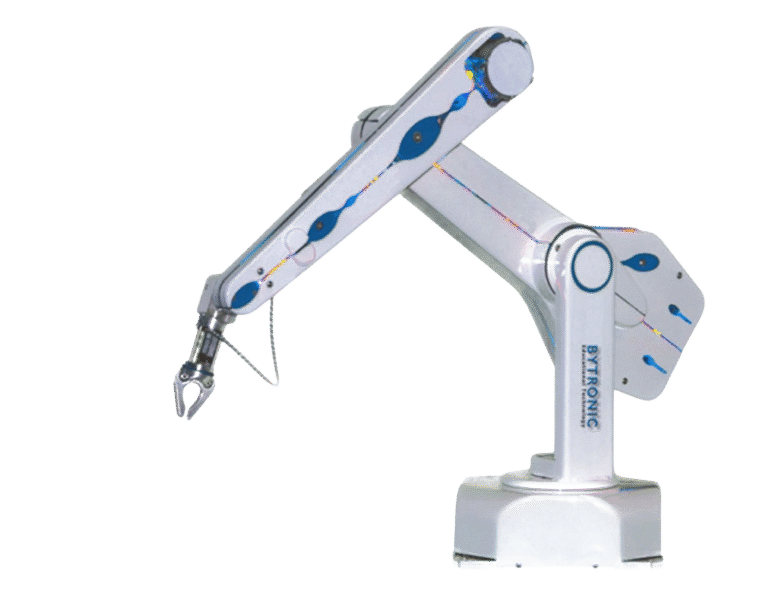

Automation

Five Axis

Robot Arm

The 5ARA is a complete self-contained five axis vertically articulated robot arm system designed for bench top automation. The hand terminates in a mounting plate for grippers, and comes standard with electric gripper fitted. The 5ARA uses light weight, high…

Marine, Naval, Hydrodinamic and Oceanograph

Wavemaker

for 3D Basins

The multi-element wavemaker is used to create long and short crested waves for either deep or shallow water. Piston type wavemakers HR Wallingford’s piston-type multi-element wavemakers are made up from a number of self contained eight-paddle modules. This enables them to be…

Categories

- Air Flow and Thermodynamics

- Alternative Energy

- Automation

- Automotive

- Chemical Engineering Equipment

- Communications

- Electronics, Control System and Instrumentation

- Fluid Mechanics

- Machine Elements and Theory of Machines

- Marine, Naval, Hydrodinamic and Oceanograph

- Mechatronics

- Miscellaneous Equipment

- Peripheral Devices

- PLC Trainers

- Process Control

- Robotic Arms

- Strength and Property of Materials

- Structures and Accessories

- Uncategorized

Product

Have an Inquiry?

Feel free to reach out to us. Our engineering experts are committed to serving you wholeheartedly.