Industrial Diesel Test Bed

Industrial Diesel Test Bed for studying low-speed, high-torque engine performance, torque vs speed, brake power, efficiency, and fuel consumption.

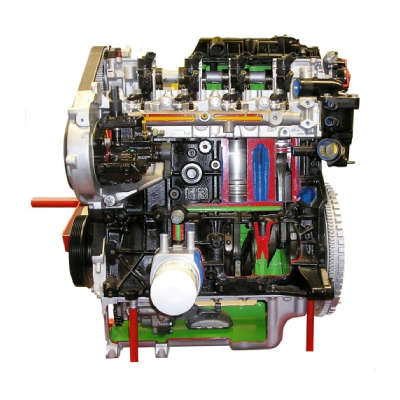

Industrial Diesel Test Bed. The test bed is intended for low speed, high torque industrial diesel engine.

The engine rests on its supports on a bed frame. The dynamometer can be either directly attached to the engine fly wheel or rests on its support and connected to the engine by a double universal joint with guard. Cooling of the engine and the dynamometer is by a cooling tower outside the engine room to minimize temperature rise. A thermo-static tank controls engine operating temperature. Engine throttle and dynamometer load control are by knobs.

Fuel tank and measuring instruments are in the engine room. Instrument panel with digital display and control buttons are in the control room.

Instruction manual is also included.

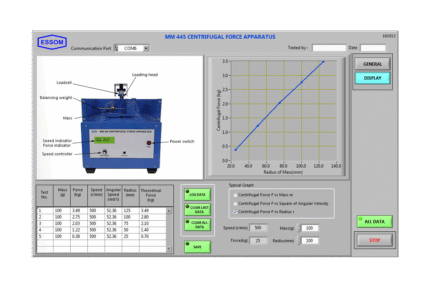

- Torque vs engine speed at various throttle settings.

- Engine brake horsepower and efficiency vs speed.

- Specific fuel consumption.

| Dynamometer: | |

| – Type | Water brake absorber. |

| – Maximum torque | At 2500 rpm. over 3300 N-m or over 850 kW. |

| – Maximum speed | 7000 rpm. |

| Cooling system : | |

| – Type | Cooling tower with circulating pumps. |

| – Capacity | Depending on engine size. |

| Thermostatic tank | Engine operating temperature control. |

| Measuring instruments: | |

| – Sensors with digital display |

|

| Calibration devices | |

| – Torque | Arm with calibration weights. |

| – Fuel flow rate | Graduated cylinder and stop watch. |

| Safety features | Low oil pressure warning lamp, and pump operation lamp. |

| Software for data display, and analysis by computer (separately supplied). | |

| Power supply | 380 V, 3 Ph, 50 Hz. Other power supply is available on request. |

Explore more engineering education products on our website at www.LABTS.co.id

| Brand | Essom |

|---|