Instrument Traverse System

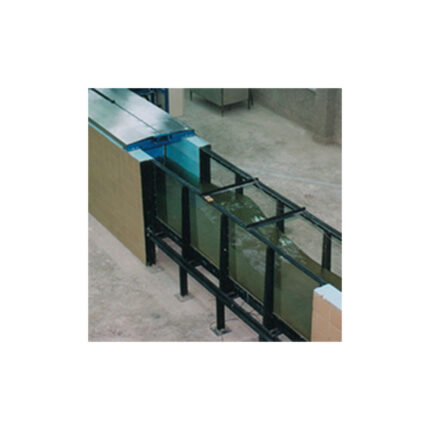

The instrument traverse system is used to move a range of physical modelling instrumentation to a variety of different positions within a flume or basin in either two or three dimensions. The instruments are secured to the vertical axis of the…

The instrument traverse system is used to move a range of physical modelling instrumentation to a variety of different positions within a flume or basin in either two or three dimensions.

The instruments are secured to the vertical axis of the system, using a variety of fixings. The vertical axis is attached to a carriage which moves along a fixed horizontal beam to allow positioning of the instruments anywhere within the flume or basin. The traverser can be controlled by a software application that logs the exact time-stamped position of the instruments to an accuracy of ±0.5mm in both vertical and horizontal axes. A stepper motor with an integral encoder is used to drive each axis into position along the carriage using a toothed belt arrangement.

Our Instrument Traverse Systems are individually designed for each application. Check the specification tab on the left for a typical specification.

Key features

- Positions a number of instruments within a flume or basin to a repeatable accuracy of ±0.5mm

- Supplied with a PC and software which controls the movement of instruments

- Lightweight, modular system

- All systems are designed to suit the client’s individual requirements for horizontal span and vertical movement

A typical specification would be:

Horizontal beam (x-axis)

- Maximum overall length: 6m

- Maximum travel: 5.8m

- Maximum velocity: 50mm/s

- Positional accuracy: ±0.5mm

Horizontal beam (y-axis)

- Overall length: 4m (dual motors required for lengths >2.0m)

- Travel: 3.8m

- Maximum velocity: 50mm/s

- Positional accuracy: ±0.5mm

Vertical beam (z-axis)

- Travel: 0.6m or 1.2m

- Maximum velocity: 25mm/s

- Positional accuracy: ±0.5mm

- Lifted weight of instruments: 5kg

- Supply voltage: 220V AC or 110V AC

In addition to the standard 2- and 3- axis systems, a second independent carriage can also be added to the horizontal beam.

| Brand | HR Wallingford |

|---|